Where Do We Use Polyurethane?

Polyurethane products have entered almost every part of our lives. Automotive, Health, Construction, Construction Machinery, Furniture, Maritime and textile sectors take the lead. For example, polyurethane-based materials are widely used in many places such as the soles of the shoes and slippers we wear, the artificial leather seats we sit on, the sponges used in beds, the insulation materials preferred in refrigerators and water heaters, parts such as consoles and steering wheels in vehicles, and the panels covering the walls of buildings.

Composites

“Composite” can be defined as a multiphase material formed by two or more materials with different chemical structures, preserving their boundaries and properties. Therefore, the composite material has properties that one of its constituent components cannot have alone. For example, in the healthcare industry, Composites are preferred especially for orthopedic applications because they have high strength and low elastic modulus.

Composite materials are more advantageous in terms of ensuring structural compatibility compared to homogeneous materials. Other advantages that polymer composites can provide are resistance to corrosion, absence of metal fatigue and release of metal ions, and reduced brittleness.

Advantages of Composite Materials

Composite products are designed to be used in harsh environmental conditions. They do not require extra paint or any other surface treatment against rust. They are resistant to many chemicals. Composites also have high UV stability. Their structural flexibility gives the products impact, bending and fracture resistance. Their thermal expansion, noise and vibration are also low. It also has advantages in terms of aesthetics and architecture. They have a smooth surface and can be produced in a wide range of colors. Although they are lighter than metals, they are stronger. They can be produced according to the desired tension, bending and impact resistance values.

They are long-lasting and have low maintenance requirements. Their application costs are reasonable due to their light weight and they are easy to install. They have the feature of self-extinguishing and delay combustion. They are dimensionally stable, meaning that their dimensions do not change due to deformation over time. Since the scrap has no material value, there is no risk of theft. For these reasons, SMC materials have been frequently preferred in infrastructure products, electrical panels, service boxes and the automotive industry in recent years.

SMC Material

The material called SMC (Hot Press Molding Pellet) is a pulp-shaped material produced by combining resin containing filling material and chopped glass fiber in the SMC machine.

It would not be wrong to compare the production of SMC material in the form of pulp to a two-stage process. In the first stage of this process, the main raw material, resin, and other auxiliary materials are mixed with the help of a high-speed mixer and the dough of the SMC material is produced. In the second stage of the process, glass fiber is combined with this dough with the help of the SMC machine.

BMC Material

The material called BMC (Hot Press Molding Compound) is a material in dough form produced by combining resin containing filling material and chopped glass fiber in a zet mixer machine.

As with SMC material, BMC pulp production consists of a two-stage process and different mixer machines are used in both stages. A fast speed mixer is used in the first stage of the process and a zet mixer (sigma mixer) is used in the second stage. While companies’ internal processes may differ, the general practice is as follows. In the first stage, BMC preliminary dough is produced by mixing the resin and other raw materials homogeneously in a high-speed mixer. The BMC pre-pulp is then taken to the second stage of the process. In the second stage of the process, horizontal mixers, known as “Zet Mixer” in our country and “Sigma Mixer” in the literature, are used.

In the second stage of the process, BMC pre-pulp and other raw materials (glass fiber, calcite and other raw materials depending on the product) are respectively taken into the mixer bowl. The mixing process is continued until a homogeneous BMC dough is obtained.

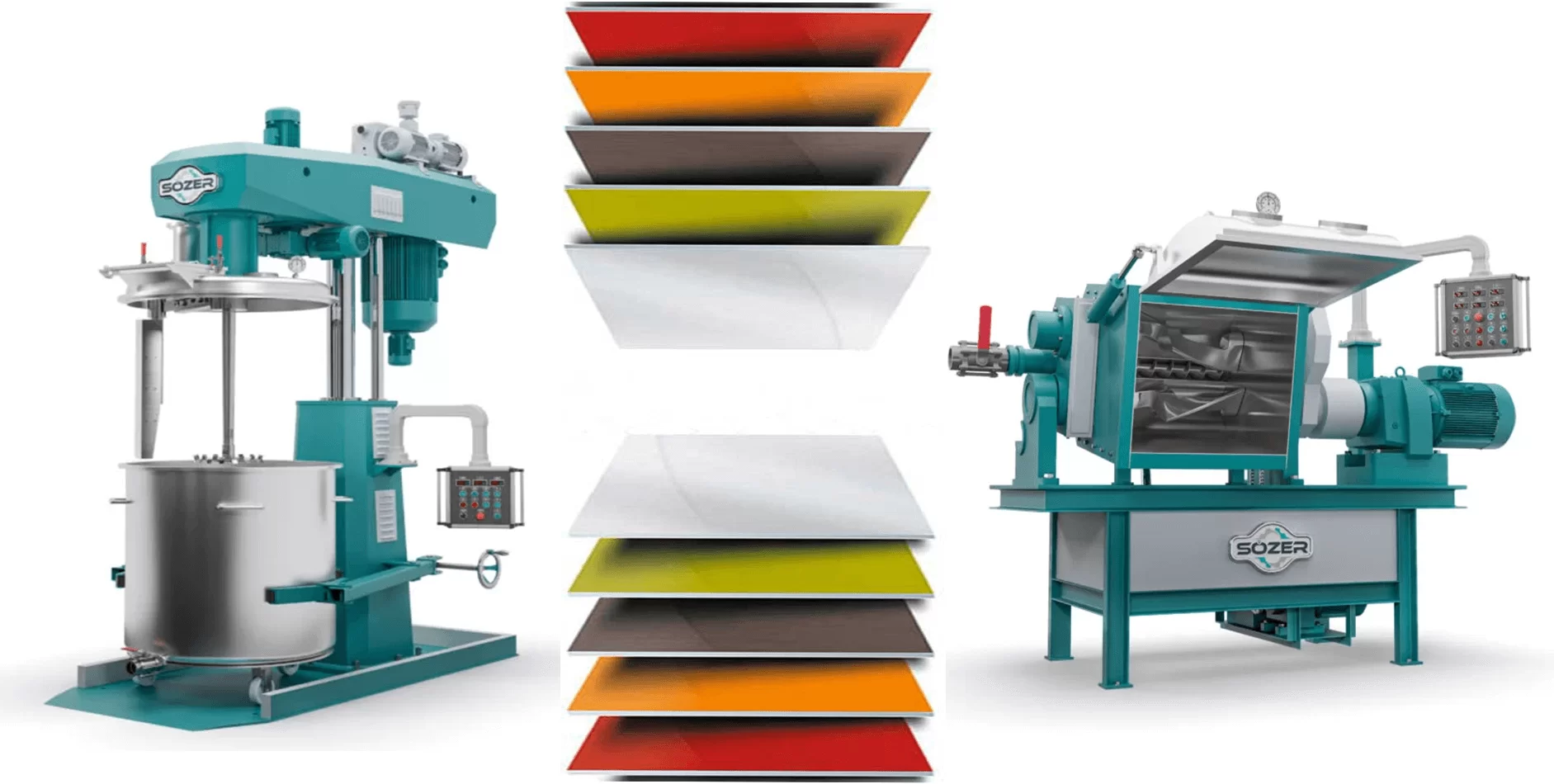

Mixers Used in the Production of SMC and BMC Materials

The following mixers are the main mixers used to produce these materials. These two mixers are the most used or preferred mixers in the composite industry.

High Speed Dissolvers with a high speed propeller on the mixing shaft, also known as Dissolvers, are the most commonly used mixers in dispersion applications. The dispersion mixer to be used for SMC and BMC preliminary dough production must have some optional features, unlike the standard high-speed mixer.

Due to the viscosity of the pre-dough of SMC and BMC materials, it would be beneficial to have a mixer with the following options:

• A more powerful main electric motor,

• Scraper arm option.

Although SMC and BMC pre-mixes do not have very intense viscosity values, the engine needs to be more powerful in order to mix the product without difficulty. The scraper arm provides additional mixing and helps product movement from different parts of the vessel. Since it continuously feeds the product to the fast-speed mixer, the scraper arm helps to obtain a homogeneous mixture in a shorter time compared to a mixer that does not have this feature. The scraper arm ensures a more homogeneous product and better heat transfer.

Zet kneaders are used to produce liquid-liquid or liquid-solid mixtures, such as fast-speed vertical mixers, which are in the group of horizontal mixers. Due to their ability to produce high torque, Zet kneaders are sometimes the only option in the production of products with very high viscosity.

All double pallet zet kneader machines have two “Z” shaped kneading blades in a “U” shaped horizontal bowl. The mixing principle of Zet mixers is based on the principle of mixing the material by crushing it between the inner wall of the bowl and the pallets and by tearing or tearing the product.

Zet kneader machine has two blades that rotate towards each other at different speeds. Each blade moves the material in the bowl in different directions, thus ensuring perfect cross-mixing of all the material. Zet kneader blades pass both to each other and to the vessel wall at the closest possible distance. This close-to-each other movement enables both shredding and tearing movements to occur, and thus the particle size of the solids can be reduced.

In order for a zet kneader to show good mixing performance, it must have at least the following features.

1. Mixing pallets must pass both to each other and to the boiler wall as close as possible. Thus, particle size can be reduced by creating high shearing. Depending on the mixer capacity, the passing distance to the vessel wall should be between 2-5 mm.

2. Two types of blade movements can be observed in Zet kneaders; These are tangential or overlapping movements. In the tangential rotation movement, the zet mixer paddles or blades rotate towards each other at different speeds. The speed of one of the blades is higher than the other. In the overlap rotation movement, the relative positions of the blades are always the same. This means that the blades rotate at the same speed. The very important point here is; If a zet mixer is to be used for a product with high viscosity such as adhesive or rubber, a zet mixer with tangential blade movement should be selected. Because tangential movement is needed to produce high viscosity products.

#zetkneader #dissolver #bmc #smc #composite #polyurethane